UMETA grease nipples

UMETA grease nipples

Depending on the application and the site of installation, we are manufacturing the grease nipples according to international standards. Apart from standard versions made of steel, zinc-plated and passivated, we are offering many types even out of brass or stainless steel. Therefore, you will always find a solution in our range of products – even for challenging applications.

Challenge us – since we are manufacturer and not a dealer!

UMETA Grease Nipples – at a glance

- 1,500 available types

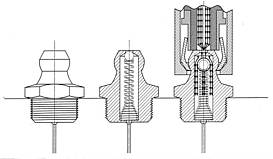

- hyraulic-type-, ball-type-, flush-type-, bayonet-, and button-head nipples

- standard versions made of zinc-plated steel, stainless steel (V2A + V4A), or brass

- case-hardened according to DIN, zinc-plated and passivated

- international product standards (e. g. DIN, ISO, SAE, BS, JIS)

- individual, custom-designed solutions

- individual packaging acc. to customers requirements

Grease nipples are manufactured of

- steel (11SMnPb30+C)

- stainless steel (V2A 1.4305, V4A 1.4401)

- brass (CuZn39 Pb3)

function of a grease nipple

Tasks of a grease nipple

- protection of the lubrication point against dirt and humidity – no sealing against internal pressure

- standardized connection to the grease gun

- essential for maintenance and repairs

Range of applications

- bearings

- hinges for machines, vehicles, industry

- cardan shafts

- drive shafts

- linear guides

- hydraulic cylinders

- drives

- chains

- axes

You are here

UMETA grease nipples

UMETA grease nipples

Direct download

Download now quickly and easily

Direct download

Download now quickly and easily

UMETA TWIN-LOCK system – The life insurance for your machines and equipment

When maintaining your high quality machines and equipment, you should absolutely avoid quasi-lubrication!

What does quasi-lubrication mean?

Upon continuous operation, abrasion can easily take place between the metal piston and the metal cylinder of the grease gun. For this reason, the grease at the top of the piston can be pressed back into the cartridge at a low operating pressure without being noticed. In spite of all effort, no grease will be transported to the lubrication spot. In order not to expose your machines to this risk, we developed the UMETA TWIN-LOCK system.

In connection with two special sealing elements, it protects the precision piston from wear upon continuous operation. By the special arrangement of the sealing elements, the UMETA TWIN-LOCK system avoids quasi-lubrication and grease escaping the piston. The sealing elements are designed in a way that they adjust themselves to the corresponding operating pressure with respect to their sealing effect.

UMETA EVER-FLOW SYSTEM

The EVER-FLOW system invented by UMETA ensures perfetct functioning of the UMETA TWIN-LOCK gun, even with thick grease and at the lowest temperatures.

This is ensured by an outlet valve equipped with a special ball stopper. Even semifluid biological grease will easily be transported by the vacuum developing during the pumping process.

This is another advantage of UMETA’s, where many other competitors’ products fail.

® UMETA HERMANN ULRICHSKÖTTER METALLWARENFABRIK GMBH & GO. KG

Technische Umsetzung by ByteCrafter | S.Faust